I’ve been toying with the idea of using ball screws on my little Sherline. Unfortunately the only way this could remotely make any kind of economic sense is if I went with the 5/8″ dia screw from Mcmaster. http://www.mcmaster.com/#ball-screws/=jwpffz The screws are $18.65 a foot and and the nuts are $29.90, which is cheap…..

I was thinking I could get that to work until I took a look at a nut… It’s an inch square. I might be able to figure out a way to squeeze it in on the Y-axis, but it would be a little crazy on the x. There just not enough room. one possibility might be to make a new saddle, but that was really more work than what I wanted to do. In addition it would reduce the work area on the Z axis. The distance between the table an the bottom rail would be reduced.

I ran across a link on cnc zone which led me to this sight which talks about makeing lead screw modifications. 5bears offers some interesting techniques on turn down a lead-screw. (I’m going to want to check this out more in detail later.

The 5/8 ball screw on a Sherline mill is probably as really dumb idea. The existing lead screw is 1/4-20 threaded rod. The price is right, but the size isn’t for a 5/8 ball screw.

The original CNC retrofit done by D&M was really shlock. Had I known this in my original bartering, I think I would have traded for a few more goodies Anyway.. D&M long since out of business..

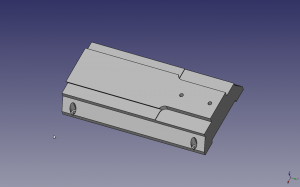

Here are a couple of pictures of the Sherline disassembled.

I don’t like where the y-axis lead screw is. It’s too close to the table. The existing motor motor mount is higher then the table. I really don’t like that. On the current Sherline CNC the motor mount is tapered for clearance.

Well, on the motor blocks. D&M basically slapped the motor mounts over the exist manual system.. Not bearings. I guess it was a way to make a quick buck.

This is also a very early model Sherline. and it has the original anti-backlash system which well it sort of sucks… The new system is much nicer, it’s meshing gears. Unfortunately retrofitting is a difficult because the center distance has changed.

So the plan for the moment to to get the rest of the components modelled in Freecad. I can use the practice with solid modeling and it will allow me to experiment with a few wacko idea without having to physically modifying the Sherline.

In My experience retrofitting increases the productivity and turnover twice than normal

Since you didn’t pop up in my askimet as spam unlike the other 796 spams currently sitting in my inbox, I’m going to assume your not a spambot.

It looks like your a start up and you attempting to increase your page ranking and trying to drum up some business.

Have a good day and good luck and wish you success.