Well repairs are complete…. Warp engine is back on line… (Hm… Was watching some trek with the kid tonight..)

On my insulation around the heater I wanted to make sure I had clearance for a socket head. When I need to remove the Nozzle (which will happen sooner or later I didn’t want to get insulation particles all over the place. Also, I might want to do the layout for the insulation before I assemble.. I probably could have avoided the slot.

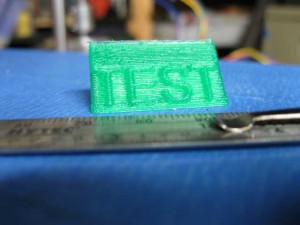

I’m curious how my mods perform. I’m keeping a log of print times to see how it does. I estimated 20-30 hours last go around, but thats just swag.

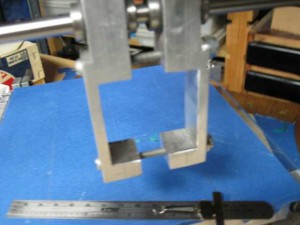

Anyway.. A few pictures.. I had a couple of people ask me what the extruder looks like.. Theres a pick as well as the mount.