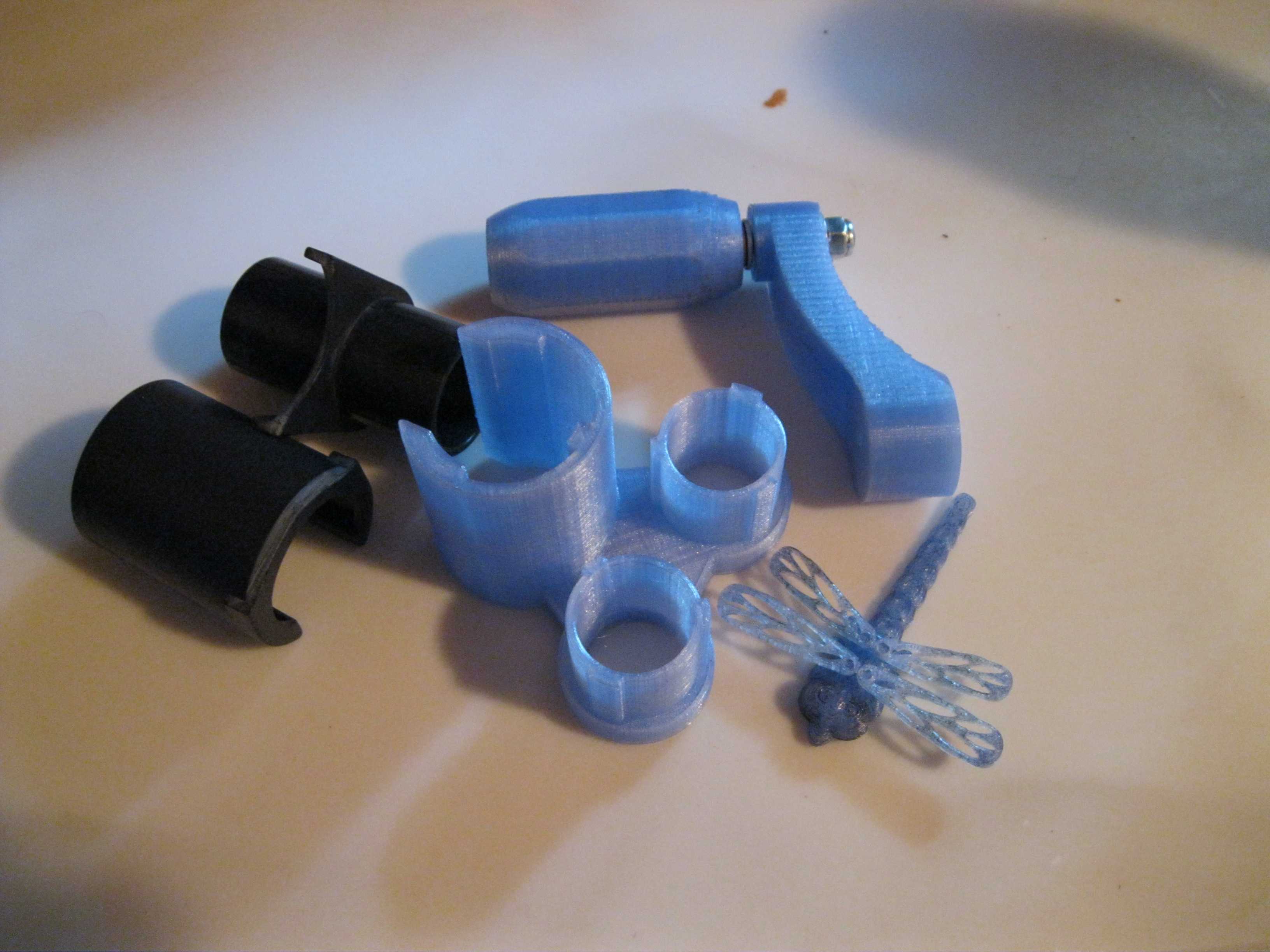

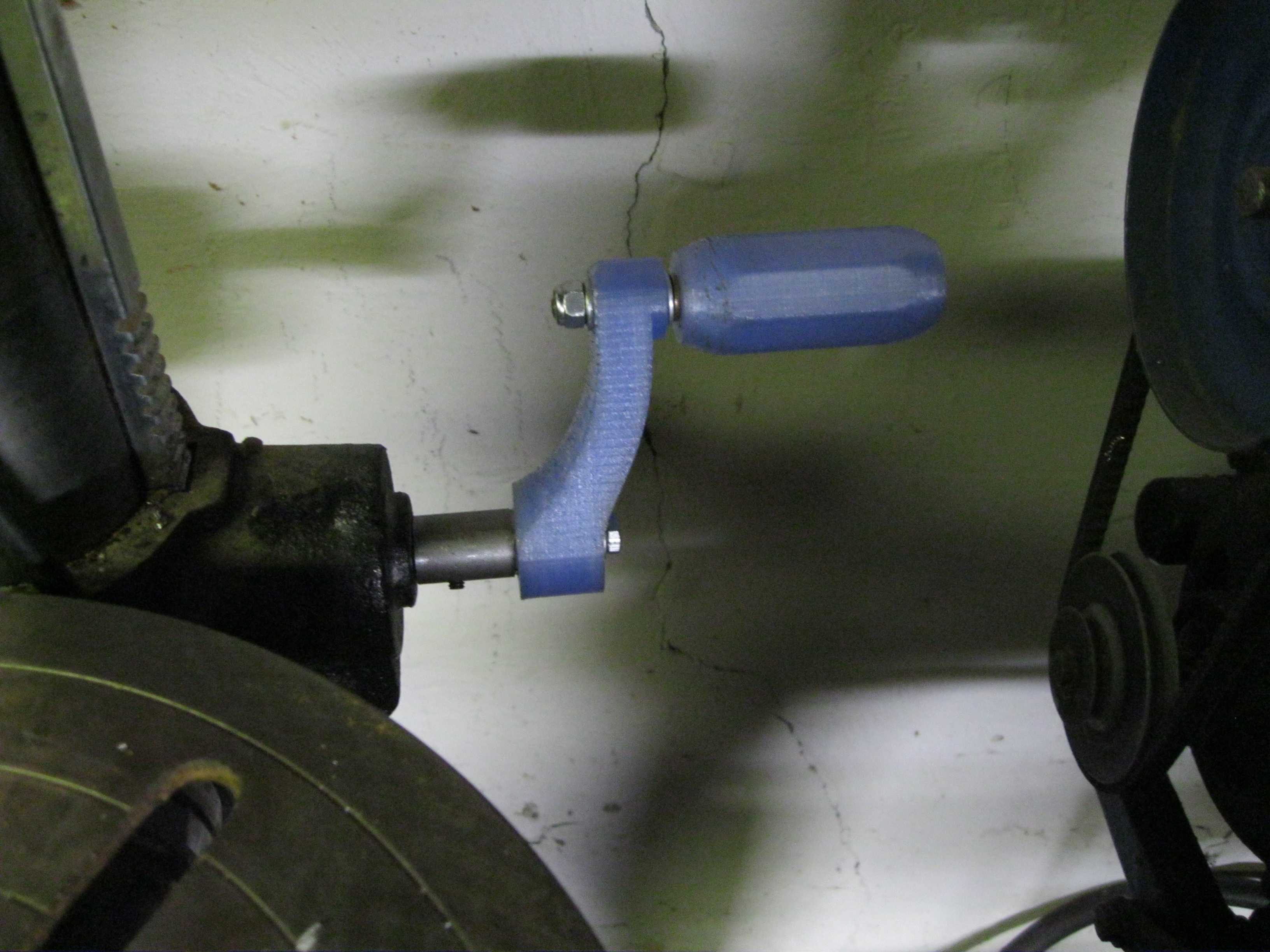

Halloween has come and gone, and once again the possessed pumpkin project is left undone.. I didn’t manage to get a couple of repair projects done. I had replaced my z-axis optical endstop hall effect and I was using a drill press handle that I had modelled as a test print.. In the midst of working on this the wife gave me a honey do which I was only too happy to comply. I have this Calhawk drill press that I bought at Menards years ago, where I broke the handle on. I’ve been wanted to make repair parts with with my 3dprinter and I finally got around to it. What’s interesting on this is that the handle-grip has a couple of oil-lite bushings to ride on. (For some reason I always got a failed print when printing the crank(Lost steps). I dialled down the acceleration parameters in Marlin and everything seemed to worked.) The 3d printed crank has a hex on it and I machined a steel adaptor for it. There was now way a setscrew in the plastic was going to take the load. I had a couple of minor design flaws.. It turns out that I had run a die on a longer 1/4 hex head and then cut it down(as opposed to using a std length bolt) Also In hind site, I should have made the grip differently to accommodate a socket to tighten the bolt. (Oth. I suppose I could have used a socket head bolt). The other project was a accessory bracket for the wife’s Miel Vacuum cleaner. I was concerned that the PLA might crack but It actually came out quite nice.