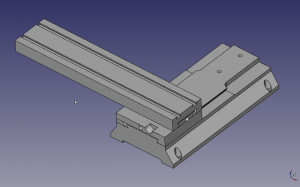

O k.. Now this is starting to get interesting. I got my Sherline table modelled. The next step is the Z-Axis support column. I was looking at my raw material inventory and I have a 4″X2 1/2 log of aluminium on hand.

k.. Now this is starting to get interesting. I got my Sherline table modelled. The next step is the Z-Axis support column. I was looking at my raw material inventory and I have a 4″X2 1/2 log of aluminium on hand.

I’m able to mount the Sherline saddle in my Ammco shaper. The vise jaws open wide enough and there seems to be plenty of clearance. I’m thinking that I probably could use the existing saddle as a template to cut the dovetails on a thicker saddle.

Of course if increased the saddle thickness, I probably need to machine a another column support.

If I go with a coarse pitch ball screw, I loose some step resolution, and motors will use more torque to move the table and saddle. Oth ball screws are much more efficient. Something to work out.