I had done a bunch of retrofits to my qu-bd printer, the last of which was installing a PTFE liner, from the rework here. buildlog.net • View topic – 15 min fix for jam free QU–BD . This fix worked and probably got about 20-30 hours of printing before I think my nozzle got clogged. The clogging I believe caused the heat to up the tub and the heat caused pla nut to sieze the stainless steel threaded plug. When I tried the removed the plug I snapped the stainless steel tub.

In order to get “stock” Ptfe tubing for this retro fit, the bore needed to be opened to 5/32.(.1563) the minor diameter of m6 threaded rod.

The minor diameter of a M6 thread ( http://www.newmantools.com/tech/threadm.htm ) 4.773 mm ( 0.187913) The leaves about .015 wall thickness to the root diameter… I can tell you that’s not enough.. I basically snapped a tube when I was trying to retrofit one and then another when I was going to remove the nozzle. It’s not a good solution.

Than got me thinking… Why not just machine a PTFE down for the tubing and while where at it machine the retaining nut out of PTFE. Sooo… I did.. I actually machined some tubes out of stainless and then proceeded to machine down some 1/4 inch ptfe tubing, and drilled the liner hole in the stainless steel tube I made to 1/8. I pressed the liner into the ss steel tube and then screwed the assembly into the upper cold end block. Actually I was pleasantly surprised how nice that when together. I suspect any other way would have been problematic.

The result was a one piece construction that was a combination retainer nut and liner. I found I assemble the liner into the tube and then screwed both pieces in the top alumimum block. I actually got a nice test print off which is where I noticed that I had a small leak going on in my heater block. ( I hind site, there is a 45 degree chamfer on the stainless steel nozzle with a flat on the front. I believe the seal on the brass nozzle/ss tube is flat on flat. I’m thinking the flat on my tube was too small with caused the leak.)

So I see this leak and I think I just can tighten this up a bit an be done… I’m doing this in the weee hours of the night/morning an should have just shut things down and try this again after a good nights rest…. but noooooooo. What I didn’t appreciate was how hard cool pla is. When I tried to screw the brass nozzle back into the aluminium heater block, I stripped out the aluminium threads in the heater block, and while I was at it, I managed to break the thermistor wires. On top of that, the pla has covered the retaining screw for the cartridge heater so I’m not sure I’ll be able to salvage that. Ugggg. (Perhaps I can chip it off) to get to the set screw.. (I’m thinking I probably I can burn off the pla from the treads of my nozzle with a propane torch…

On the plus side, except for lack of flat issue on my ss tube, It didn’t break and I was torque the begebers out of it. I had drilled it out to .125 for the liner and that seemed to worked real nice.

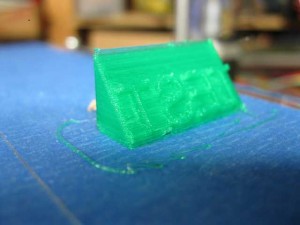

Also, I had thought I could “catch” the pla by extending the PTFE rod and putting a nice angled guide… It turns out that this didn’t work to well. I think I’m going to need to cut down one the height a bit… The cooling fan is mouted to the front of the motor and gets in the way. (At some point, I’m going to move the fan down and a bunch of other mods, which at this point I don’t think there going to be anything left of the qu-bd…

I’m thinking the single piece ptfe think could work and is worth one more try.. I just need to get the leak fixed which I think I just need to face off .005-.010″ from the front and it will be fine.