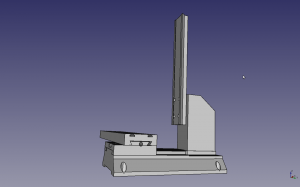

I would say that I have partially accomplished one of my goals, insofar as that I’ve gotten a little Freecad practise under my belt. Freecad has come a long way, and still has a ways to go, but from my perspective, I found modelling the Sherline in Freecad to me more relaxing than frustrating. There’s a few hiccups in the software that broke the mood but it’s not too bad.

I would say that I have partially accomplished one of my goals, insofar as that I’ve gotten a little Freecad practise under my belt. Freecad has come a long way, and still has a ways to go, but from my perspective, I found modelling the Sherline in Freecad to me more relaxing than frustrating. There’s a few hiccups in the software that broke the mood but it’s not too bad.

The Sherline that I measured and modeled was obtained in barter. It was originally a manual machine with a shoddy CNC conversion done by a third party. Outside of some misc dings, the ways seem to be lightly used. As discussed previously the CNC adaptation of the bearing arrangement is just slock.

The Sherline leadscrew arrangement is cost effective for manual mill. The older style mill with I have, has a backlash adjustment that’s sort of pain to set. The new design is actually quite nice. Unfortunately, I think it would probably be a pain to retrofit.

Sherlines Stepper motor mounts are designed for 200 step Nema 23 motors which seems to match my D&M motors as well.

I think I need to do a little cost comparison here.. I just want to compare the cost of getting my mill upgraded with using Sherline components, versus what it would run me on buying the ball screw parts and other parts.

The Sherline sight is not the most friendly sight to move around in. Here is a link to the motor mount installation.

It appears have a Model 5000, so I would need the P/N 6700 retro kit.

| P/N inch/metric | NAME | WT. | PRICE |

| 6700/6710 | CNC Upgrade Kit, 5000-series Mills | 2.5 lb. | $250.00 |

——

|

50171 |

LEADSCREW, X-AXIS, CNC (Inch) |

18.00 |

|

50161 |

LEAD SCREW, “Y” AXIS, CNC (Inch) | 12.00 |

I was doing some research and I ran across some nice links on conversion that I wanted to look at in more detail.

http://www.cnczone.com/forums/benchtop_machines/122462-pm-45_cnc_conversion_rf45-7.htm

http://www.prototrains.com/shermill/mill.jpg

So if wanted use some 5/8 ball screws

Needs to be reballed. http://groups.yahoo.com/group/CAD_CAM_EDM_DRO/message/86634

Products

| Line | Quantity | Product | Ships | Unit price | Total | |

|---|---|---|---|---|---|---|

| 1 | 1 pack | 9528K11 | Bearing Quality E52100 Alloy Steel Ball 1/8″ Diameter, Grade 25, packs of 100 | in the morning | $2.90 pack | 2.90 |

| 2 | 1 each | 5966K26 | Ball Screw 5/8″ Dia, 13/64″ Lead, 2′ Length | in the morning | $37.30 each | 37.30 |

| 3 | 1 each | 5966K26 | Ball Screw 5/8″ Dia, 13/64″ Lead, 1′ Length | in the morning | $18.65 each | 18.65 |

| 4 | 3 each | 5966K16 | Ball Nut, 5/8″ Dia, 13/64″ Lead, 778lb Load Cap, Square | in the morning | $29.90 each | 89.70 |

| Merchandise total | $148.55 | |||||

Ok… good enough for the preliminary cost analysis… I have material already to make a modified saddle and support base plus I really want to put b all screws on this. Hopefully, I won’t go way over the cost of a Sherline retrofit. So I have a ~130 bucks to play with, before this becomes a really dumb idea. I ordered ball screws from Mcmaster and they were there the next day.. The labor portion is being written off against learning experience. (Thats a nice thing about a hobby)

all screws on this. Hopefully, I won’t go way over the cost of a Sherline retrofit. So I have a ~130 bucks to play with, before this becomes a really dumb idea. I ordered ball screws from Mcmaster and they were there the next day.. The labor portion is being written off against learning experience. (Thats a nice thing about a hobby)

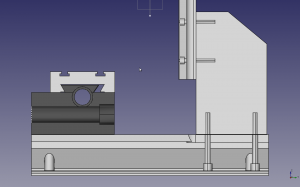

To get this to work, I think I’m going to basically need to do two major modifications. I need to make the saddle much thicker, so I can get the 5/8 shafts to go through the saddle, I’m thinking I’m just going to have the ball screw nuts screw into the saddle. I think I’m going to have make a new support column that’s a little taller and drill a hole to run the screw through it and mount the motor on the back of the column.

This is just a preliminary attempt at modifying the saddle. As you can see there are some issues.. But it’s a start.