I was talking to Dan Heeks in the IRC and he seems to think that the problem is somewhere here: http://code.google.com/p/heekscad/source/browse/trunk/src/Constraint.cpp#332

Dan submitted http://code.google.com/p/heekscad/source/detail?r=1285

It seem like he was in a hurry, and unforturnately his fix didn’t do the trick. I’ve been pounding on this solver for a few days trying to understand how it works and it feels like the core code is rock solid.

Any I’m pretty sure there are two bugs at work here. I think Dan Heeks targeted the area of what was wrong.. Hmm. I took a C++ class I wonder if I can figure it out.

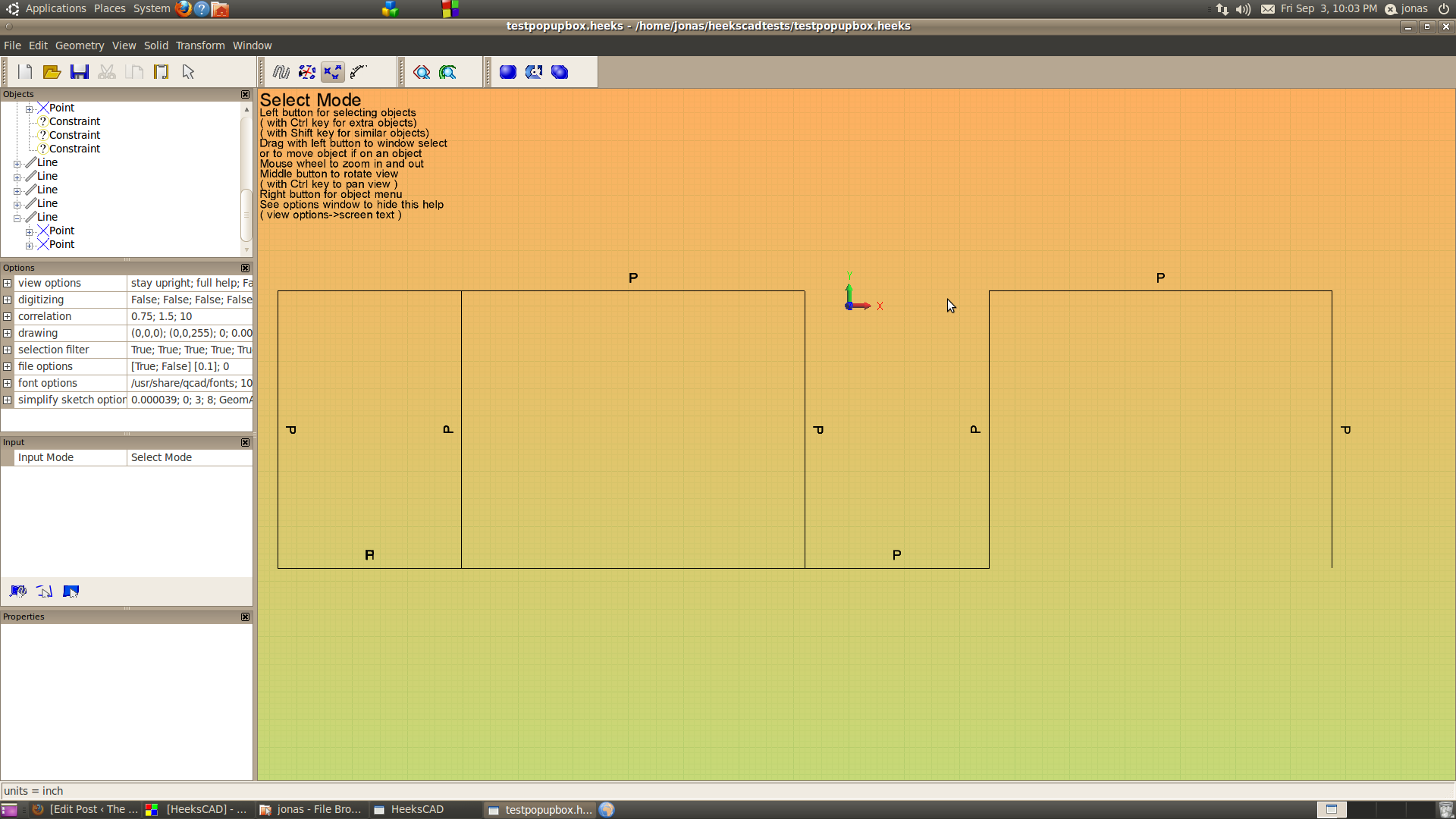

It using my test 2 file http://code.google.com/p/heekscad/issues/detail?id=304

Experiment #1: Failed

<HeeksCAD_Document>

−

<Sketch title=”Sketch” id=”1″>

−

<Line col=”0″ id=”1″>

<Point col=”0″ x=”-45.5″ y=”-7″ z=”0″ id=”1″/>

<Point col=”0″ x=”-45.5″ y=”17.75″ z=”0″ id=”2″/>

</Line>

−

<Line col=”0″ id=”2″>

<Point col=”0″ x=”-45.5″ y=”17.75″ z=”0″ id=”3″/>

<Point col=”0″ x=”-14.5″ y=”17.75″ z=”0″ id=”4″/>

</Line>

−

<Line col=”0″ id=”3″>

<Point col=”0″ x=”-14.5″ y=”17.75″ z=”0″ id=”5″/>

<Point col=”0″ x=”-14.5″ y=”-7″ z=”0″ id=”6″/>

</Line>

−

<Line col=”0″ id=”4″>

<Point col=”0″ x=”-14.5″ y=”-7″ z=”0″ id=”7″/>

<Point col=”0″ x=”-45.5″ y=”-7″ z=”0″ id=”8″/>

</Line>

</Sketch>

<Constraint type=”CoincidantPointConstraint” angle=”AbsoluteAngleHorizontal” length=”0″ obj1_id=”8″ obj1_type=”2″ obj2_id=”1″ obj2_type=”2″ id=”4″/>

<Constraint type=”CoincidantPointConstraint” angle=”AbsoluteAngleHorizontal” length=”0″ obj1_id=”2″ obj1_type=”2″ obj2_id=”3″ obj2_type=”2″ id=”1″/>

<Constraint type=”AbsoluteAngleConstraint” angle=”AbsoluteAngleVertical” length=”0″ obj1_id=”1″ obj1_type=”3″ id=”5″/>

<Constraint type=”CoincidantPointConstraint” angle=”AbsoluteAngleHorizontal” length=”0″ obj1_id=”4″ obj1_type=”2″ obj2_id=”5″ obj2_type=”2″ id=”2″/>

<Constraint type=”AbsoluteAngleConstraint” angle=”AbsoluteAngleHorizontal” length=”0″ obj1_id=”2″ obj1_type=”3″ id=”6″/>

<Constraint type=”CoincidantPointConstraint” angle=”AbsoluteAngleHorizontal” length=”0″ obj1_id=”6″ obj1_type=”2″ obj2_id=”7″ obj2_type=”2″ id=”3″/>

<Constraint type=”AbsoluteAngleConstraint” angle=”AbsoluteAngleVertical” length=”0″ obj1_id=”3″ obj1_type=”3″ id=”7″/>

<Constraint type=”AbsoluteAngleConstraint” angle=”AbsoluteAngleHorizontal” length=”0″ obj1_id=”4″ obj1_type=”3″ id=”8″/>

</HeeksCAD_Document>

I suspected the problem might be with the overloaded constructor firing.

I but a break point in all the constructors and I drew a line and set the vertical constraint.

This Constructor function fired:

Constraint::Constraint(EnumConstraintType type,EnumAbsoluteAngle angle, ConstrainedObject* obj)

In the source constraint.cpp, HeeksObj* Constraint::ReadFromXMLElement(TiXmlElement* pElem)

Constraint(etype,eangle,length,obj1,obj2)

Ok.. I hacked the code a bit to get the same constructor to fire with no success. Now this is a more than a little irritating. I know that AbsoluteAngleHorizontal can me set when manually drawing. So… I think the more that I make the file read look like the manual drawing, it will sooner or later work… Right?????

I think I need to start documenting the experiments:

HeeksObj* Constraint::ReadFromXMLElement(TiXmlElement* pElem)

{

const char* type=0;

EnumConstraintType etype=(EnumConstraintType)0;

const char* angle=0;

EnumAbsoluteAngle eangle=(EnumAbsoluteAngle)0;

double length=0;

int obj1_id=0;

int obj2_id=0;

int obj1_type=0;

int obj2_type=0;

ConstrainedObject* obj1=0;

ConstrainedObject* obj2=0;

// get the attributes

std::string type_name = “”; //THIS IS A JT HACK

for(TiXmlAttribute* a = pElem->FirstAttribute(); a; a = a->Next())

{

std::string name(a->Name());

if(name == “type”){

type = a->Value();

type_name =a->Value();//THIS IS A JT HACK

}

else if(name == “angle”){angle = a->Value();}

else if(name == “length”){length = a->DoubleValue();}

else if(name == “obj1_id”){obj1_id = a->IntValue();}

else if(name == “obj1_type”){obj1_type = a->IntValue();}

else if(name == “obj2_id”){obj2_id = a->IntValue();}

else if(name == “obj2_type”){obj2_type = a->IntValue();}

}

//Ugh, we need to convert the strings back into types

for(unsigned i=0; i < sizeof(ConstraintTypes); i++)

{

if(strcmp(ConstraintTypes[i].c_str(),type)==0)

{

etype = (EnumConstraintType)i;

break;

}

}

for(unsigned i=0; i < sizeof(AbsoluteAngle); i++)

{

if(strcmp(AbsoluteAngle[i].c_str(),angle)==0)

{

eangle = (EnumAbsoluteAngle)i;

break;

}

}

//Get real pointers to the objects

obj1 = (ConstrainedObject*)wxGetApp().GetIDObject(obj1_type,obj1_id);

obj2 = (ConstrainedObject*)wxGetApp().GetIDObject(obj2_type,obj2_id);

// JT HACKS JST

if (type_name== “AbsoluteAngleConstraint”){

//Constraint *cAbs = new Constraint(obj1);

//if(obj1)obj1->constraints.push_back(cAbs);

obj1->SetAbsoluteAngleConstraint(eangle);

}

else

{

Constraint *c = new Constraint(etype,eangle,length,obj1,obj2);

if(obj1)obj1->constraints.push_back(c);

if(obj2)obj2->constraints.push_back(c);

}

//Don’t let the xml reader try to insert us in the tree

return NULL;

I thought for sure this would work but it didn’t ;(

I got this idea by setting the break point on all the Constraint constructors to see which one fired when I set a vertical in sketch mode when it fired by hitting ctrl-shift-F7 to step out of the function and see what triggered this.

“void ConstrainedObject::SetAbsoluteAngleConstraint(EnumAbsoluteAngle angle)” fired ” constraints.push_back(new Constraint(AbsoluteAngleConstraint,angle,this));”

which was fired by

“class SetLineVertical:public Tool run() ” fired line_for_tool->SetAbsoluteAngleConstraint(AbsoluteAngleVertical);

which was fired by

void HeeksCADapp::on_menu_event(wxCommandEvent& event) t->Run();

which was fired by

void CGraphicsCanvas::OnMenuEvent(wxCommandEvent& event) fired wxGetApp().on_menu_event(event); (which I guess was the top event)

I guess time for experiment 2. It looks like src/HLine.cpp is point wx opengl and opencascade converge. At this point, I don’t want to dig any deeper. This is where things get pretty heavy deeper. Maybe I can get something to work at this layer

Ok… this looks interesting

class SetLineVertical:public Tool{

public:

void Run(){

line_for_tool->SetAbsoluteAngleConstraint(AbsoluteAngleVertical);

SolveSketch((CSketch*)line_for_tool->Owner());

wxGetApp().Repaint();

}

const wxChar* GetTitle(){return _(“Toggle Vertical”);}

wxString BitmapPath(){return _T(“new”);}

const wxChar* GetToolTip(){return _(“Set this line to be vertical”);}

};

Experment#2: Failed

If wonder what will happen if I invoke sketchsolve at this point. What the heck… worth a try..

It seems that the coincident points constraints works, but my little experiment had no affect.

Oh… This sucks.

HeeksObj* Constraint::ReadFromXMLElement(TiXmlElement* pElem)

{

const char* type=0;

EnumConstraintType etype=(EnumConstraintType)0;

const char* angle=0;

EnumAbsoluteAngle eangle=(EnumAbsoluteAngle)0;

double length=0;

int obj1_id=0;

int obj2_id=0;

int obj1_type=0;

int obj2_type=0;

ConstrainedObject* obj1=0;

ConstrainedObject* obj2=0;

// get the attributes

std::string type_name = “”; //THIS IS A JT HACK

for(TiXmlAttribute* a = pElem->FirstAttribute(); a; a = a->Next())

{

std::string name(a->Name());

if(name == “type”){

type = a->Value();

type_name =a->Value();//THIS IS A JT HACK

}

else if(name == “angle”){angle = a->Value();}

else if(name == “length”){length = a->DoubleValue();}

else if(name == “obj1_id”){obj1_id = a->IntValue();}

else if(name == “obj1_type”){obj1_type = a->IntValue();}

else if(name == “obj2_id”){obj2_id = a->IntValue();}

else if(name == “obj2_type”){obj2_type = a->IntValue();}

}

//Ugh, we need to convert the strings back into types

for(unsigned i=0; i < sizeof(ConstraintTypes); i++)

{

if(strcmp(ConstraintTypes[i].c_str(),type)==0)

{

etype = (EnumConstraintType)i;

break;

}

}

for(unsigned i=0; i < sizeof(AbsoluteAngle); i++)

{

if(strcmp(AbsoluteAngle[i].c_str(),angle)==0)

{

eangle = (EnumAbsoluteAngle)i;

break;

}

}

//Get real pointers to the objects

obj1 = (ConstrainedObject*)wxGetApp().GetIDObject(obj1_type,obj1_id);

obj2 = (ConstrainedObject*)wxGetApp().GetIDObject(obj2_type,obj2_id);

// JT HACKS JST

if (type_name== “AbsoluteAngleConstraint”){

//Constraint *cAbs = new Constraint(obj1);

//if(obj1)obj1->constraints.push_back(cAbs);

obj1->SetAbsoluteAngleConstraint(eangle);

//line_for_tool->SetAbsoluteAngleConstraint(AbsoluteAngleVertical);

SolveSketch((CSketch*)obj1->Owner());

}

else

{

Constraint *c = new Constraint(etype,eangle,length,obj1,obj2);

if(obj1)obj1->constraints.push_back(c);

if(obj2)obj2->constraints.push_back(c);

}

//Don’t let the xml reader try to insert us in the tree

return NULL;

I need to step away from this for a while..