To anyone reading this, my apologies on the roughness of these notes… I’m sure there’s plenty of typo’s grammar mistakes. I was sort of time-strapped when I did this.

It was sort of irritating that I had to reformat my drive form scratch, I think think to document it the first time around. Hopefully this will help someone out.

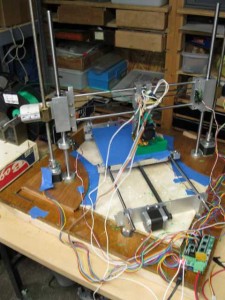

I had a T3410 E-machine desktop in inventory that I wanted to use for my 3d printer instead of my laptop.

I had setup it up for ubuntu 12.04 and spent about 1 1/2 days getting the thing setup. I was literally in the last steps of getting things setup when I did something incredibly stupid.

I was in the middle of compiling slicer when I thought I kill the lights… Well, it turns out that my computer was run off that power strip…. Well, that really mucked up the works and I need to live cd to boot… Rather than attempting a repair, I decided to reformat the drive and start from scratch. This time I decided to keep notes on what I did, (on the off chance I’ll do something stupid like this again.)

We’ll lets see if I can find my research links..

The first that I need to tweak was my video card.

I’ve got all kinds of horizontal lines going on after installing 12.04.

I guess the fix was here.

http://askubuntu.com/questions/227487/horizontal-line-across-screen-at-startup

So.. press Ctrl-alt-f1 to open terminal session and here are the magic steps needed to get that straightened out.

sudo apt-get –purge autoremove

sudo apt-get clean

sudo apt-get update

sudo apt-get install nvidia-experimental-304

sudo apt-get install nvidia-settings-experimental-304

rebooting.. and problem has gone away…

78/////+/+41962-555g5 (that was the cat saying hello..)

One small rant here. When I installed I said to automatically update. I then went to work..

Now when got up home and ran the update manager, I have 571 updates 303.mb… (that’s one of the reasons this took me so long the first time.) When I run the update manager I get kinds of problems because the update manager is having issues because of updates not being made… (sort of oxy moronic)..

Anyway… Time for the command line..

I did a quick google here and I came up with this.

http://askubuntu.com/questions/141119/what-is-the-equivalent-terminal-command-of-update-manager

and suggests this command:

sudo apt-get dist-upgrade

Hrrrgg.. Slow connection this is going to take a while.

Lets.. Next thing on the list

I had downed preconfigured sprinter software from here: http://ultimachine.com/sites/default/files/UltiMachineRAMPS1-4Sprinter.zip . and I had wound up copying it from my laptop…

The thing is that I need to download Arduino 0023 to get that to run..

I got that from here: http://www.arduino.cc/en/Main/Software

Ok.. So first thing I get is that java: not found.. (I suppose I need to wait for the updates to finish.

(Done finally… I had burned an install disk for 12.04 shortly after it came out… That might have been part of the problem.

Since my gui is now working… went with the ubuntu software center and entered Java and installed Java 7 Runtime.

Ok… Now to get Repertier-host downloaded from but first I need mono… Might was well go with monDevelop which I thing should have the run time with it…

so… to www.repetier.com/download and go with linux .85c

Now you need to run ./configureFirst.sh

The one issue I have with Repertier is that you can’t just come back and it’s done… You have to hit a yes every now and then.

Ok… Back to Arduino IDE 0023. When I try running a program I get “Cannot run program “Avr-g++”: error=2, no such file or directory.” I remember that I just need to load something.

Got it from here. http://code.google.com/p/arduino/wiki/BuildingArduino The command is:

sudo apt-get install gcc-avr avr-libc

Next error:

In file included from Sprinter.cpp:6:0:

pins.h:217:3: error: #error Oops! Make sure you have ‘Arduino Mega’ selected from the ‘Tools -> Boards’ menu.

Sprinter.cpp: In function ‘void setup()’:

Sprinter.cpp:246:1: error: ‘DIO55_DDR’ was not declared in this scope

Sprinter.cpp:246:5: error: ‘DIO55_PIN’ was not declared in this scope

Sprinter.cpp:249:1: error: ‘DIO61_DDR’ was not declared in this scope

Sprinter.cpp:249:5: error: ‘DIO61_PIN’ was not declared in this scope…..

Thanks an easy one, I just need to go Tool->Board and select Arduino Mega 2560 on the pull down…

Next error.:

In file included from /usr/lib/gcc/avr/4.5.3/../../../avr/include/util/delay.h:44:0,

from /usr/lib/gcc/avr/4.5.3/../../../avr/include/avr/delay.h:37,

from /home/jonasthomas/Arduino0023/arduino-0023/hardware/arduino/cores/arduino/wiring_private.h:30,

from /home/jonasthomas/Arduino0023/arduino-0023/hardware/arduino/cores/arduino/WInterrupts.c:34:

/usr/lib/gcc/avr/4.5.3/../../../avr/include/math.h:426:15: error: expected identifier or ‘(’ before ‘double’

/usr/lib/gcc/avr/4.5.3/../../../avr/include/math.h:426:15: error: expected ‘)’ before ‘>=’ token

Hmm.. Amusing found the soluction in my own blog… http://www.metalshaperman.com/?p=1461

Next one:

Binary sketch size: 20014 bytes (of a 258048 byte maximum)processing.app.SerialNotFoundException: Serial port ‘COM1’ not found. Did you select the right one from the Tools > Serial Port menu? at processing.app.Serial.<init>(Serial.java:153) at processing.app.Serial.<init>(Serial.java:76) at processing.app.debug.Uploader.flushSerialBuffer(Uploader.java:75) at processing.app.debug.AvrdudeUploader.uploadViaBootloader(AvrdudeUploader.java:93) at processing.app.debug.AvrdudeUploader.uploadUsingPreferences(AvrdudeUploader.java:56) at processing.app.Sketch.upload(Sketch.java:1603) at processing.app.Sketch.exportApplet(Sketch.java:1568) at processing.app.Sketch.exportApplet(Sketch.java:1524) at processing.app.Editor$DefaultExportHandler.run(Editor.java:2293) at java.lang.Thread.run(Thread.java:722)

Hmm… that’s a new one (well maybe not…)

http://blog.markloiseau.com/2012/05/install-arduino-ubuntu/

Ok… I needed permissions setup on the port..

Author suggests this: sudo chmod a+rw /dev/ttyACM0

Ok… that did it… So arduino firmware is all setup… Lets see if I can can repetierHost to work…

Looking at readme.txt it was talking about.

usermod -a -G dialout yourUserName

My as well do that too.

Ok… tried connect… That didn’t work…. Tried to slice…. No joy either..

Here are the messages”

01:22:28.357 : OpenGL version:2.1.2 NVIDIA 304.4801:22:28.358 : OpenGL extensions:GL_ARB_color_buffer_float GL_ARB_compressed_texture_pixel_storage GL_ARB_conservative_depth GL_ARB_copy_buffer GL_ARB_depth_clamp GL_ARB_depth_texture GL_ARB_draw_buffers GL_ARB_ES2_compatibility GL_ARB_explicit_attrib_location GL_ARB_fragment_program GL_ARB_fragment_program_shadow GL_ARB_fragment_shader GL_ARB_framebuffer_object GL_ARB_get_program_binary GL_ARB_half_float_pixel GL_ARB_half_float_vertex GL_ARB_imaging GL_ARB_internalformat_query GL_ARB_map_buffer_alignment GL_ARB_map_buffer_range GL_ARB_multisample GL_ARB_multitexture GL_ARB_occlusion_query GL_ARB_occlusion_query2 GL_ARB_pixel_buffer_object GL_ARB_point_parameters GL_ARB_point_sprite GL_ARB_provoking_vertex GL_ARB_robustness GL_ARB_sampler_objects GL_ARB_separate_shader_objects GL_ARB_shader_objects GL_ARB_shading_language_100 GL_ARB_shading_language_420pack GL_ARB_shading_language_include GL_ARB_shadow GL_ARB_sync GL_ARB_texture_border_clamp GL_ARB_texture_compression GL_ARB_texture_cube_map GL_ARB_texture_env_add GL_ARB_texture_env_combine GL_ARB_texture_env_crossbar GL_ARB_texture_env_dot3 GL_ARB_texture_float GL_ARB_texture_mirrored_repeat GL_ARB_texture_non_power_of_two GL_ARB_texture_rectangle GL_ARB_texture_rg GL_ARB_texture_storage GL_ARB_texture_swizzle GL_ARB_timer_query GL_ARB_transpose_matrix GL_ARB_vertex_array_bgra GL_ARB_vertex_array_object GL_ARB_vertex_buffer_object GL_ARB_vertex_program GL_ARB_vertex_shader GL_ARB_window_pos GL_ATI_draw_buffers GL_ATI_texture_float GL_ATI_texture_mirror_once GL_S3_s3tc GL_EXT_texture_env_add GL_EXT_abgr GL_EXT_bgra GL_EXT_blend_color GL_EXT_blend_equation_separate GL_EXT_blend_func_separate GL_EXT_blend_minmax GL_EXT_blend_subtract GL_EXT_compiled_vertex_array GL_EXT_Cg_shader GL_EXT_depth_bounds_test GL_EXT_direct_state_access GL_EXT_draw_range_elements GL_EXT_fog_coord GL_EXT_framebuffer_blit GL_EXT_framebuffer_multisample GL_EXT_framebuffer_object GL_EXT_gpu_program_parameters GL_EXT_multi_draw_arrays GL_EXT_packed_depth_stencil GL_EXT_packed_pixels GL_EXT_pixel_buffer_object GL_EXT_point_parameters GL_EXT_provoking_vertex GL_EXT_rescale_normal GL_EXT_secondary_color GL_EXT_separate_shader_objects GL_EXT_separate_specular_color GL_EXT_shadow_funcs GL_EXT_stencil_two_side GL_EXT_stencil_wrap GL_EXT_texture3D GL_EXT_texture_compression_dxt1 GL_EXT_texture_compression_s3tc GL_EXT_texture_cube_map GL_EXT_texture_edge_clamp GL_EXT_texture_env_combine GL_EXT_texture_env_dot3 GL_EXT_texture_filter_anisotropic GL_EXT_texture_format_BGRA8888 GL_EXT_texture_lod GL_EXT_texture_lod_bias GL_EXT_texture_mirror_clamp GL_EXT_texture_object GL_EXT_texture_sRGB GL_EXT_texture_sRGB_decode GL_EXT_texture_storage GL_EXT_texture_swizzle GL_EXT_timer_query GL_EXT_vertex_array GL_EXT_vertex_array_bgra GL_EXT_x11_sync_object GL_EXT_import_sync_object GL_IBM_rasterpos_clip GL_IBM_texture_mirrored_repeat GL_KTX_buffer_region GL_NV_alpha_test GL_NV_blend_minmax GL_NV_blend_square GL_NV_complex_primitives GL_NV_copy_depth_to_color GL_NV_depth_clamp GL_NV_ES1_1_compatibility GL_NV_fbo_color_attachments GL_NV_fence GL_NV_float_buffer GL_NV_fog_distance GL_NV_fragdepth GL_NV_fragment_program GL_NV_fragment_program_option GL_NV_fragment_program2 GL_NV_framebuffer_multisample_coverage GL_NV_half_float GL_NV_light_max_exponent GL_NV_multisample_filter_hint GL_NV_occlusion_query GL_NV_packed_depth_stencil GL_NV_pixel_data_range GL_NV_point_sprite GL_NV_primitive_restart GL_NV_register_combiners GL_NV_register_combiners2 GL_NV_texgen_reflection GL_NV_texture_barrier GL_NV_texture_compression_vtc GL_NV_texture_env_combine4 GL_NV_texture_expand_normal GL_NV_texture_lod_clamp GL_NV_texture_rectangle GL_NV_texture_shader GL_NV_texture_shader2 GL_NV_texture_shader3 GL_NV_vertex_array_range GL_NV_vertex_array_range2 GL_NV_vertex_program GL_NV_vertex_program1_1 GL_NV_vertex_program2 GL_NV_vertex_program2_option GL_NV_vertex_program3 GL_NVX_conditional_render GL_OES_compressed_paletted_texture GL_OES_depth24 GL_OES_depth32 GL_OES_depth_texture GL_OES_element_index_uint GL_OES_fbo_render_mipmap GL_OES_get_program_binary GL_OES_mapbuffer GL_OES_packed_depth_stencil GL_OES_point_size_array GL_OES_point_sprite GL_OES_rgb8_rgba8 GL_OES_read_format GL_OES_standard_derivatives GL_OES_texture_3D GL_OES_texture_float GL_OES_texture_float_linear GL_OES_texture_half_float GL_OES_texture_half_float_linear GL_OES_texture_npot GL_OES_vertex_array_object GL_OES_vertex_half_float GL_SGIS_generate_mipmap GL_SGIS_texture_lod GL_SGIX_depth_texture GL_SGIX_shadow GL_SUN_slice_accum 01:22:28.358 : OpenGL renderer:GeForce 6100/integrated/SSE2/3DNOW!01:22:28.358 : Using fast VBOs for rendering is possible01:22:55.677 : No such file or directory01:23:26.830 : No such file or directory01:23:49.058 : <Slic3r> Can’t locate Boost/Geometry/Utils.pm in @INC (@INC contains: /home/jonasthomas/RepetierHost/Slic3r/lib /etc/perl /usr/local/lib/perl/5.14.2 /usr/local/share/perl/5.14.2 /usr/lib/perl5 /usr/share/perl5 /usr/lib/perl/5.14 /usr/share/perl/5.14 /usr/local/lib/site_perl .) at /home/jonasthomas/RepetierHost/Slic3r/lib/Slic3r.pm line 32.01:23:49.058 : <Slic3r> BEGIN failed–compilation aborted at /home/jonasthomas/RepetierHost/Slic3r/lib/Slic3r.pm line 32.01:23:49.058 : <Slic3r> Compilation failed in require at /home/jonasthomas/RepetierHost/Slic3r/slic3r.pl line 13.01:23:49.058 : <Slic3r> BEGIN failed–compilation aborted at /home/jonasthomas/RepetierHost/Slic3r/slic3r.pl line 13.

If memory serves me correctly I fixed the slicer issue by renaming the slicer folder name doing a git pull and compiling from source. The incanctations where a bit unusual… Lets see if I can find them.

I can’t find the link talking about this problem and the fix… But I found these instructions for pulling from git and building. https://github.com/alexrj/Slic3r/wiki/Running-Slic3r-from-git-on-GNU-Linux I’m wondering if at this point, I should pull repetier-host down from github and just compile the whole thing from scratch… But… for know this is what I’m doing.

Hmm.. Didn’t work… This is what I did…:

jonasthomas@rockbot1:~$ cd RepetierHost

jonasthomas@rockbot1:~/RepetierHost$ ls

APACHE-LICENSE-2.0.txt OpenTK.xml

changelog.txt README.txt

configureFirst.sh repetierHost

data RepetierHost.application

empty.txt RepetierHost.exe

installDependenciesDebian RepetierHost.exe.manifest

installDependenciesFedora Repetier-Host-licence.txt

OpenTK.Compatibility.dll RepetierHost.pdb

OpenTK.Compatibility.dll.config RepetierHost.vshost.application

OpenTK.Compatibility.xml RepetierHost.vshost.exe

OpenTK.dll SomethingWeird hreonSlic3r

OpenTK.dll.config version.txt

OpenTK.GLControl.dll workdirectory

OpenTK.GLControl.xml

jonasthomas@rockbot1:~/RepetierHost$ sudo apt-get install git build-essential libgtk2.0-dev libwxgtk2.8-dev libwx-perl libmodule-build-perl libnet-dbus-perl

[sudo] password for jonasthomas:

Sorry, try again.

[sudo] password for jonasthomas:

Reading package lists… Done

Building dependency tree

Reading state information… Done

git is already the newest version.

libgtk2.0-dev is already the newest version.

libmodule-build-perl is already the newest version.

libnet-dbus-perl is already the newest version.

libwx-perl is already the newest version.

libwxgtk2.8-dev is already the newest version.

build-essential is already the newest version.

0 upgraded, 0 newly installed, 0 to remove and 10 not upgraded.

jonasthomas@rockbot1:~/RepetierHost$

jonasthomas@rockbot1:~/RepetierHost$ sudo apt-get install cpanminus

Reading package lists… Done

Building dependency tree

Reading state information… Done

cpanminus is already the newest version.

0 upgraded, 0 newly installed, 0 to remove and 10 not upgraded.

jonasthomas@rockbot1:~/RepetierHost$ sudo git clone https://github.com/alexrj/Slic3r.git

Cloning into ‘Slic3r’…

remote: Counting objects: 12160, done.

remote: Compressing objects: 100% (7185/7185), done.

remote: Total 12160 (delta 6414), reused 10411 (delta 4700)

Receiving objects: 100% (12160/12160), 4.02 MiB | 242 KiB/s, done.

Resolving deltas: 100% (6414/6414), done.

jonasthomas@rockbot1:~/RepetierHost$ cd Slic3r

jonasthomas@rockbot1:~/RepetierHost/Slic3r$ sudo apt-get install libwx-perl

Reading package lists… Done

Building dependency tree

Reading state information… Done

libwx-perl is already the newest version.

0 upgraded, 0 newly installed, 0 to remove and 10 not upgraded.

jonasthomas@rockbot1:~/RepetierHost/Slic3r$ sudo cpanm Boost::Geometry::Utils Math::Clipper \

> Math::ConvexHull Math::ConvexHull::MonotoneChain Math::Geometry::Voronoi Math::PlanePath Moo Wx XML::SAX

–> Working on Boost::Geometry::Utils

Fetching http://www.cpan.org/authors/id/A/AA/AAR/Boost-Geometry-Utils-0.15.tar.gz … OK

Configuring Boost-Geometry-Utils-0.15 … OK

==> Found dependencies: ExtUtils::Typemaps::Default

–> Working on ExtUtils::Typemaps::Default

Fetching http://www.cpan.org/authors/id/S/SM/SMUELLER/ExtUtils-Typemaps-Default-1.03.tar.gz … OK

Configuring ExtUtils-Typemaps-Default-1.03 … OK

==> Found dependencies: ExtUtils::Typemaps

Found ExtUtils::Typemaps 3.18 which doesn’t satisfy 3.18_03.

! Installing the dependencies failed: Installed version (3.18) of ExtUtils::Typemaps is not in range ‘3.18_03’

! Bailing out the installation for ExtUtils-Typemaps-Default-1.03.

! Installing the dependencies failed: Module ‘ExtUtils::Typemaps::Default’ is not installed

! Bailing out the installation for Boost-Geometry-Utils-0.15.

–> Working on Math::Clipper

Fetching http://www.cpan.org/authors/id/A/AA/AAR/Math-Clipper-1.22.tar.gz … OK

Configuring Math-Clipper-1.22 … OK

==> Found dependencies: ExtUtils::Typemaps::Default

! Installing the dependencies failed: Module ‘ExtUtils::Typemaps::Default’ is not installed

! Bailing out the installation for Math-Clipper-1.22.

Math::ConvexHull is up to date. (1.04)

Math::ConvexHull::MonotoneChain is up to date. (0.01)

Math::Geometry::Voronoi is up to date. (1.3)

–> Working on Math::PlanePath

Fetching http://www.cpan.org/authors/id/K/KR/KRYDE/Math-PlanePath-106.tar.gz … OK

Configuring Math-PlanePath-106 … OK

Building and testing Math-PlanePath-106 … OK

Successfully installed Math-PlanePath-106 (upgraded from 105)

Moo is up to date. (1.002000)

Wx is up to date. (0.9922)

–> Working on XML::SAX

Fetching http://www.cpan.org/authors/id/G/GR/GRANTM/XML-SAX-0.99.tar.gz … OK

Configuring XML-SAX-0.99 … OK

==> Found dependencies: XML::NamespaceSupport, XML::SAX::Base

–> Working on XML::NamespaceSupport

Fetching http://www.cpan.org/authors/id/P/PE/PERIGRIN/XML-NamespaceSupport-1.11.tar.gz … OK

Configuring XML-NamespaceSupport-1.11 … OK

Building and testing XML-NamespaceSupport-1.11 … OK

Successfully installed XML-NamespaceSupport-1.11

–> Working on XML::SAX::Base

Fetching http://www.cpan.org/authors/id/G/GR/GRANTM/XML-SAX-Base-1.08.tar.gz … OK

Configuring XML-SAX-Base-1.08 … OK

Building and testing XML-SAX-Base-1.08 … OK

Successfully installed XML-SAX-Base-1.08

Building and testing XML-SAX-0.99 … OK

Successfully installed XML-SAX-0.99

4 distributions installed

jonasthomas@rockbot1:~/RepetierHost/Slic3r$ ./slic3r.pl

Can’t locate Boost/Geometry/Utils.pm in @INC (@INC contains: /home/jonasthomas/RepetierHost/Slic3r/lib /etc/perl /usr/local/lib/perl/5.14.2 /usr/local/share/perl/5.14.2 /usr/lib/perl5 /usr/share/perl5 /usr/lib/perl/5.14 /usr/share/perl/5.14 /usr/local/lib/site_perl .) at /home/jonasthomas/RepetierHost/Slic3r/lib/Slic3r.pm line 32.

BEGIN failed–compilation aborted at /home/jonasthomas/RepetierHost/Slic3r/lib/Slic3r.pm line 32.

Compilation failed in require at ./slic3r.pl line 13.

BEGIN failed–compilation aborted at ./slic3r.pl line 13.

jonasthomas@rockbot1:~/RepetierHost/Slic3r$

Ahhh… Here it is:

http://forums.reprap.org/read.php?263,215641,216643#msg-216643

OMG yes it works!

For those with the same problem, delete all files and folders, or rename containing slic3r.

Then follow source download instructions here:

[slic3r.org]

ignore the part underneath that talks about installing other crap first. Just do the top four lines and it works, installs everything checks everything.

When your finished you can enter slic3r with ./slic3r.pl and it will work!

In other words:

$ git clone git://github.com/alexrj/Slic3r

$ cd Slic3r

$ sudo perl Build.PL

$ sudo cpan Wx

Cool… That got slic3r working in repartier….

It seems like I’m having issues getting a connection going in repartier..

Hmm.Been there done that… I spent some time head scratching on that one as well.

What I wound up doing is looking at the port that my arduino IDE selected and then went into Config printer settings in repartier-host and selected that one as well. (Also I’m not positive you need put I had my laptop baud rate set at 115200. I did the same on my desktop and I got the darn thing to work.