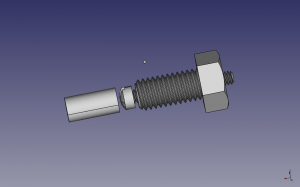

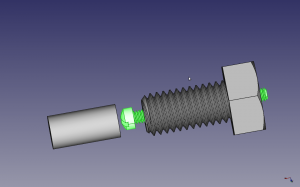

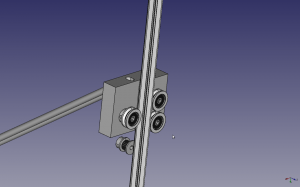

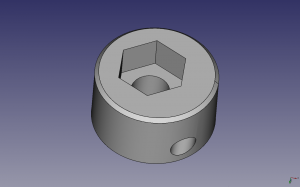

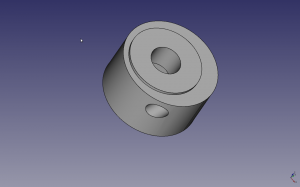

I wasn’t liking the eccentric on my first iteration. The eccentric didn’t seem solid enough to me. Well this is my second iteration. Instead of a metal plate I’m going with a 3d printed bracket. The eccentric locates in a countersunk hole. I added a cross hole to the eccentric. At this point, I’m going to use the hole for leverage to manually preload the rail and hopefully just hold everything in with friction, if not I’m thinking adding a spring load to hold the rail snug via spring tension.

It seems like this should work.

Next thing to work out is the ball joint sockets.

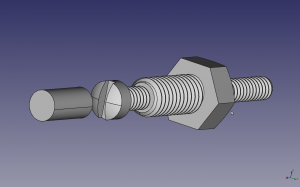

What I think be cool to do is to add a differential screw to adjust the magnetic pull on the ball socket. This is going to take more than a few iterations till I get that to a point where I’m ready to fab that up. If you’re interested reading about differential screws, hear is a good reference: http://en.wikipedia.org/wiki/Differential_screw

I made up a matrix show differential movement for various thread pitches.

I think my first iteration is going to be 10-24 Internal thread with a M8-1.24mm thread.

The differential works out to .0075 per rotation (assuming I did my math correctly)

http://engineershandbook.com/Tables/threadlimits.htm

So.. I need the major diameter on 10-24 => 0.190

Minor diameter of M8-1.25 (6.231)=> 0.2453

That works out to .027 wall thickness which works for me…

http://mdmetric.com/tech/LimitingDimensions.htm

I might as well go Nylon on the M8 to keep down the weight. http://www.mcmaster.com/#94175a805/=uf974f

And giggles and snorts try a 10-24X 2 to start. http://www.mcmaster.com/#90280a253/=uf9eac

Duh.. Supposedly that was the smallest diameter bolt head available.. I need to shrink things down.

A 3-48 seems to fit way better.. Ok.. I need to think this out.

If I turn a M8-1.25 one revolution its going to move 1.25/25.4 = .0492 ” <———

If I keep the 3-48 stationary and rotate a nut it will translate 1/48 =0.0208 ——>

-.0492 + .0208 = .0242 (which seems a bit coarse) Lets give a 6-32 a (with is .018 /Rev)

It looks good as far as the magnet clearance goes.

It would be nice to boost the metric bolt size to a M10 but it appears that I can’t get a 1.25 pitch in nylon the pitch goes up to 1.5 which is a differential of .027… Yech..