This is starting to get interesting… My PTFE liner mod is still holding up… Continous printing so far…

I’m thinking I should make a filament cleaner… repercussions of the last clog really screwed me up..

I was looking at filament cleaners on thingiverse and I stumbled on the link for the MK-7 extruder…. What’s curious is the glowing reviews…

Seeing the the qu-bd was it’s clone. seems like the MK-7 should have had the same issue… http://www.thingiverse.com/thing:11734 go figure..

Anyway… Here’s a link for filament clearners http://www.thingiverse.com/search/basic/page:1?q=filament%20cleaner . There’s a bunch of options I need to perculate on this a bit…

Tonights print was spool bearing adapters.. For some reason, this print has been problematic for me… This go around, I had the table well aligned and the tip about a sheet of paper way from the table (Guestimating .004) Since I have alignment close to perfect, I had the first layer print out sort of mushed… This compounded for the first couple of layers and I had scraping which resulted in a slight skip.. which worked itself out. OTH… That was probably the best adhesion I’ve ever done.

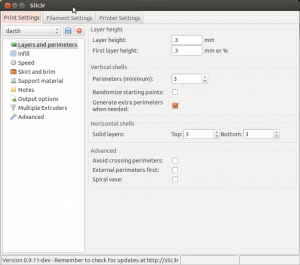

I’m looking at the Slicer settings and I should have trimmed down the thickness of the first layer. This is something that I need to research a bit more.

Also, when I tried to raise up .120″ by going G1 Z3.048 I fell signficantly short.. (I could swear that I had that done correctly…) I’m going to need to read up on the sprinter G-code commands

http://reprap.org/wiki/G-code#Unbuffered_G_command

; generated by Slic3r 0.9.11-dev on 2013-07-25 at 14:05:06

; layer_height = .3

; perimeters = 3

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = .2

; perimeter_speed = 30

; infill_speed = 60

; travel_speed = 90

; nozzle_diameter = .35

; filament_diameter = 1.74

; extrusion_multiplier = 1

; perimeters extrusion width = 0.35mm

; infill extrusion width = 0.37mm

; solid infill extrusion width = 0.37mm

; top infill extrusion width = 0.37mm

; first layer extrusion width = 0.60mmG21 ; set units to millimeters

M107

M104 S215 ; set temperature

G28 ; home all axes

G1 Z5 F5000 ; lift nozzle

M109 S215 ; wait for temperature to be reached

G90 ; use absolute coordinates

G92 E0

M82 ; use absolute distances for extrusion

G1 F1800.000 E-1.00000

G92 E0

G1 Z0.300 F5400.000

G1 X64.964 Y36.002

Next steps:

- Review proper settings for first layer… (Review http://reprap.org/wiki/Triffid_Hunter%27s_Calibration_Guide) for guidence and make adjustment

- Put .003 shim under the low side of the y-axis to see if we can improve parallelism..

- Need to figure why a manual move doesnt seem to be working. Probably should run a 20mm cube to see if it’s really 20mm height. I need to verify that my firmware settings are correct (hopefully) or fix them.

- Assuming settings are correct, I might need to increase E just a tiny bit.